DRICONPLUS drift eliminators

What are they?

DRICONPLUS drift eliminators are suitable for cooling towers, air handling units and gas turbine air intake ducts.

The baffles are made of filled polypropylene and are corrosion-free and easy to assemble with the main sides facing each other parallel and horizontally

DRICONPLUS is top quality, innovative and internationally patented.

How do they work?

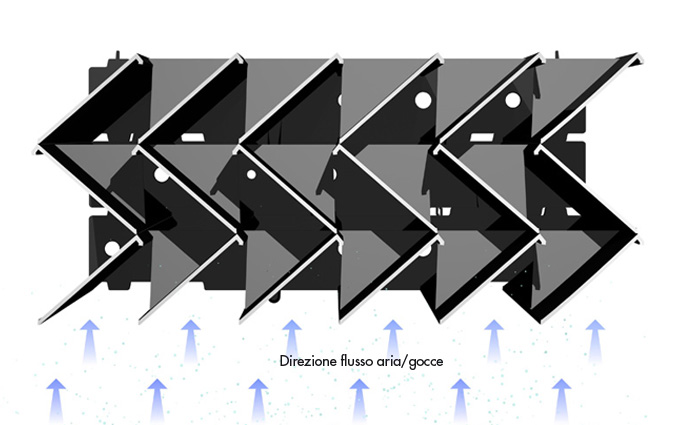

When assembled together to create a unit, DRICONPLUS drift eliminators represent a valid tool in order to reduce/avoid the water droplets entrained in a natural or forced air flow.

Coupled together in series to the air flow direction, DRICONPLUS drift eliminators raise the droplet retention capacity: the number of units can be increased so that the desired efficiency rate is attained. This makes DRICONPLUS unique when compared to other drift eliminators.

Fields of application:

DRICONPLUS drift eliminators are mainly used in all types of cooling towers, air handling units and gas turbine air intake ducts.

Cooling Towers

Cooling towers are used in the thermal recovery of cooling water used by equipment or industrial processes. When the water to be cooled comes into contact with a substantial external air flow, evaporation of a small portion of water is brought about. The evaporation process takes away heat from residual water and transfers it to the air.

This system is by far the most economical and most compact choice when it comes to cooling large quantities of water.

The salient data relevant to an evaporative cooling process regard water consumption and can be quantified as follows:

• Evaporation

Approximately one litre per 600 Kcal/h (0.6977 KW) being dispersed

• Blow down

resulting from both the quality of raw water and the type of treatment in use

• Drift

In some countries it is strictly defined; where not imposed, a drift loss of 0.005% of the circulating water is considered acceptable.

While the loss for evaporation cannot be reduced and the blow down value can be adjusted within limits, reducing the drift loss has become an issue over the years.

The reason for this is the need for Public Authorities to control the spread of the Legionnaires' disease.

All this has led to the creation of DRICONPLUS drift eliminator with efficiency which can be increased up to 100%:

As a matter of fact DRICONPLUS bars can be coupled to create several sections even at different points in time until the desired efficiency is met.

Air Handling Units

The need to humidify air serves:

reasons of wellbeing

industrial processes

preservation of good in air-conditioned areas.

One of the most common systems serving this range is made of a section having one or more sets of spraying nozzles, a sump to collect non-absorbed water and a pumping system for delivering liquid solution from the sump to the nozzles.

Besides these elements, it is normal practice to design a section for separation and retention of the droplets entrained in the air flow.

If the air flow is loaded with droplets, the system components may be damaged as a result and water may be delivered into the air ducts or even to the areas to be conditioned: this ultimately results in problems, damages or even the spread of bacteria.

The circulating air must be appropriate both in terms of temperature and humidity and no residual process water must be released in the air.

Vertically assembled, DRICONPLUS drift eliminator can be installed in air handling units and also for this application several bars can be inserted in series up to desired efficiency.

"Reordering" of air flow streams prior to the handling sections may be needed: a simple line of DRICONPLUS bars will definitively be highly economical as well as efficient to the scope.

Air suction in gas turbines

The air used in gas turbines as an oxidising agent must be good quality and free of foreign material.

In order to ensure purity and protect the suction elements, filtering parts to withhold dirt are put in place.

When present, also water droplets can cause serious damage to turbines; for this reason, suction elements are protected by drift eliminators.

DRICONPLUS drift eliminators are particularly suited for this specific application thanks to their high efficiency which can be rated according to actual needs and increased on demand.

Why DRICONPLUS?

In cooling towers entrained water droplets are often an expensive and unproductive loss of water as well as a potential means of spread of the Legionnaires' disease.

In air treatment units, entrained droplets - deriving both from winter humidification compartments and cooling and dehumidification coils - can damage downstream components, air distribution ducts and even air-conditioned environments.

The air taken in by gas turbine air intake ducts must be high quality so the turbine can be kept clean and free from droplets.

DRICONPLUS drift eliminators' proven retention capacity may be modified upon request during installation or after, until the desired efficiency has been obtained.

Being mechanically robust, DRICONPLUS endures temperatures up to above 90 °C., is easy to handle, clean and sanitise.

DRICONPLUS gathers four of the most salient features of these components, namely: the efficiency required (which can be increased); robustness (both mechanical and to temperatures), interchangeability with most currently used components and cost efficiency.